Why Are Microchips Rising in Price, and When Are Shortages Going to Subside?

After the onset of the COVID pandemic in 2020, the world moved online. Companies and their employees had to stock up on new computers, smartphones, tablets, cameras, and other communication devices to keep on with their jobs and studies in isolation.

In turn, this triggered off an extremely high demand and a spike in prices for equipment components.

In this write-up, we’ll try to figure out:

- the reasons behind the extraordinary shortage of microchips

- when microchip shortages will finally subside

What Are the Reasons behind Microchip Shortages?

Demand Exceeded Supply

The first signs of the coming shortages of microchips emerged back in 2020. During the lockdown, microchip factories drastically cut down on the manufacture of new components. By the time demand recovered, stocks were already exhausted, which resulted in the heaviest shortage of microchips in the industry’s history.

After a surge in demand for microchips for smartphones and laptops throughout Q1 – Q2 2020, the car industry started to recover from the coronavirus crisis in Q3 2020, which put additional pressure on supply, eventually leading to a full-blown collapse. The car industry bought up most of the remaining stocks. Just imagine, some 100 microchips are necessary to produce one new car.

As a result of the shortages of components, even Apple had to push off the launch of new iPhone models at one point. It’s no secret that Apple outsources rather than manufactures components for its gadgets. Instead, Samsung scored some advantage thanks to its in-house manufacture of microchips.

Eventually, the shortage of microchips at the beginning of 2021 reached 30% of the market.

Artificial Shortage

Many electronics manufacturers accuse South Korea and Taiwan of collusion to monopolize the market and artificially inflating microchip prices. Is this the case? Yes, it is! The two countries have established an effective microchip monopoly. In 2020, when the demand for communication equipment saw a major upsurge, they created an artificial shortage.

In the pre-COVID era, the capacity utilization of microchip factories ranged between 50 and 75%. Such partial capacity utilization was embedded in the operational setup to enable the manufacturers to respond to any changes in demand in good time and produce more microchips as necessary.

Meanwhile, the demand for laptops and smartphones grew by 25 – 30%, and it would seem that microchip factories could fully cover the demand. Believe it or not, they suspended the manufacture of microchips for cars and focused exclusively on electronics components instead, thereby creating shortages and driving overpricing for the car industry.

By the way, the net profit of microchip companies between 2020 and 2021 increased by 19%. A mere coincidence? We think not!

Political Conflict between Hong Kong and China

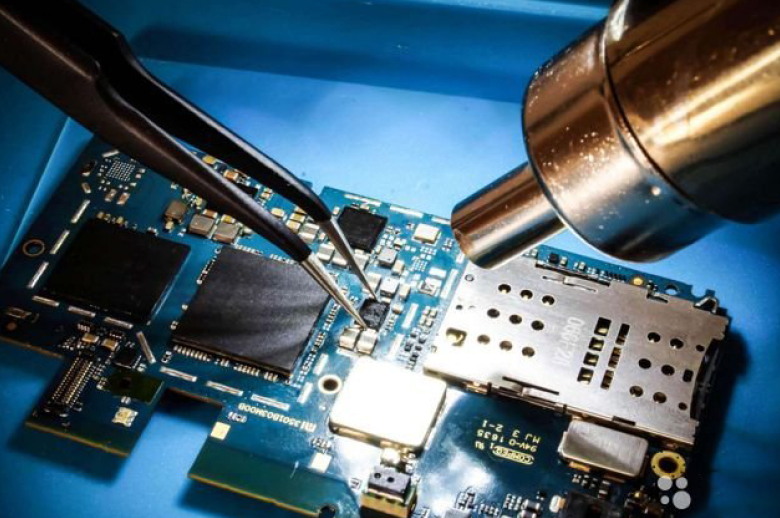

It's no secret that all sorts of copies of spare parts for smartphones, laptops, and other gadgets are made in China. We’re talking about small factories, which put together and assemble fully-functional spare parts from a host of small components rather than manufacture spare parts from scratch.

Such components, in turn, are supplied from different countries and regions of China, including Hong Kong. As you know, political tensions between the PRC and Hong Kong run high. Customs checks have been tightened, with virtually every bag and scrap of paper being subject to a close inspection. The lockdown measures put in place after the outbreak of the coronavirus pandemic made things even worse. It takes little mathematics to see how the convergence of these developments affected the spares market.

In the good old days, the microchips manufactured in Taiwan shipped by boat to Hong Kong, where grannies with checked bags were already waiting for deliveries to take them to Shenzhen.

Considering these developments, the supply of microchips from Hong Kong to China has so far virtually been cut off. Thus, the factories that made the copies of spare parts have lost access to source materials as the market grapples with heavy shortages of spares for smartphones and other gadgets.

When Will the Situation Rebound and the Shortages End?

Lack of Investment

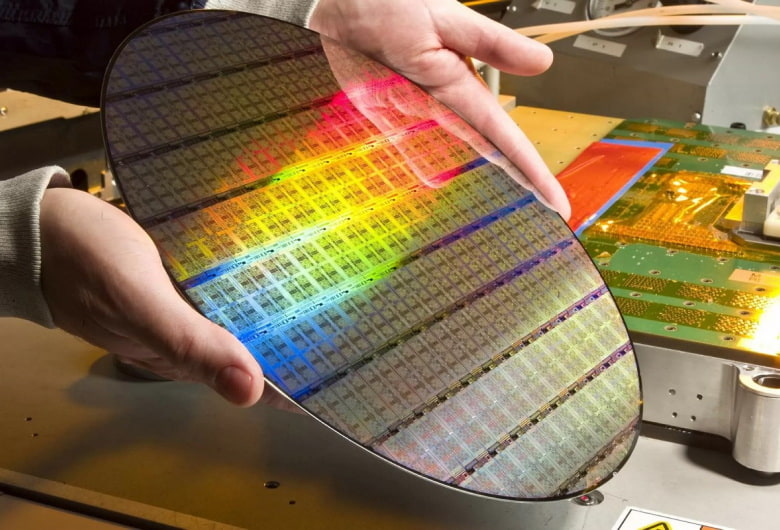

C.C. Wei, CEO of TSMC, the global leader in the microchip market, says the industry has long suffered from a lack of investment. Microchip production involves an extremely expensive process. As a saying among microelectronics developers and manufacturers goes: “This isn’t rocket science, it’s much more sophisticated!”

Microchips used in most advanced gadgets today have some 5 nanometers in size. For comparison, the average thickness of a human hair is 100,000 nanometers. Inside, each microchip consists of dozens or even hundreds of layers of material, some of which are a mere atom thick. It’s hard to wrap your mind around those values, isn’t it?

Microchip factories are the cleanest places on earth. The facilities where the chips are manufactured are hundreds of times cleaner than neurosurgical operating rooms. They are sterile. There isn’t even a speck of dust in the air there because just one speck of dust could spoil an entire batch of microchips and result in millions’ worth of losses. This is the number one reason why building a microchip factory rough and ready just won’t work.

Americans Building New Factories

Recently, word got out that the crisis in the microchip market made Americans think about building factories at home.

TSMC is poised to be put in charge of the construction. They’ve already bought land and all the necessary equipment for the construction of six new factories. The existing factories started recruiting and training employees to work in the new factories. Based on early projections, the first manufacturing lines won’t launch until 2024. However, even their launch won’t be able to quickly flatten out or bridge the shortage.

When Will Microchip Shortages Finally Subside?

So far, no one can give an exact answer to this question because the market has just started to recover. Meanwhile, medical experts are already warning of potential new strains of coronavirus and other diseases. No one knows yet what impact this will have on the market. But even if the diseases recede and the world bounces back to normal, manufacturing companies will still need at least a year to bridge existing shortages, which means that the return of the microchip market to normalcy shouldn't be expected at least until 2022 or even 2023.

How will this affect the end customer? As simple as that: prices for both spares and finished electronic products will continue to grow.

We’ve seen worse than that, you can say that again! The most important thing is that everyone remains safe and sound, and the ALL SPARES online store is there for you to help you find and buy any necessary spare or microchip.